Reliable Electrical Repair & Maintenance for Diesel Fleets

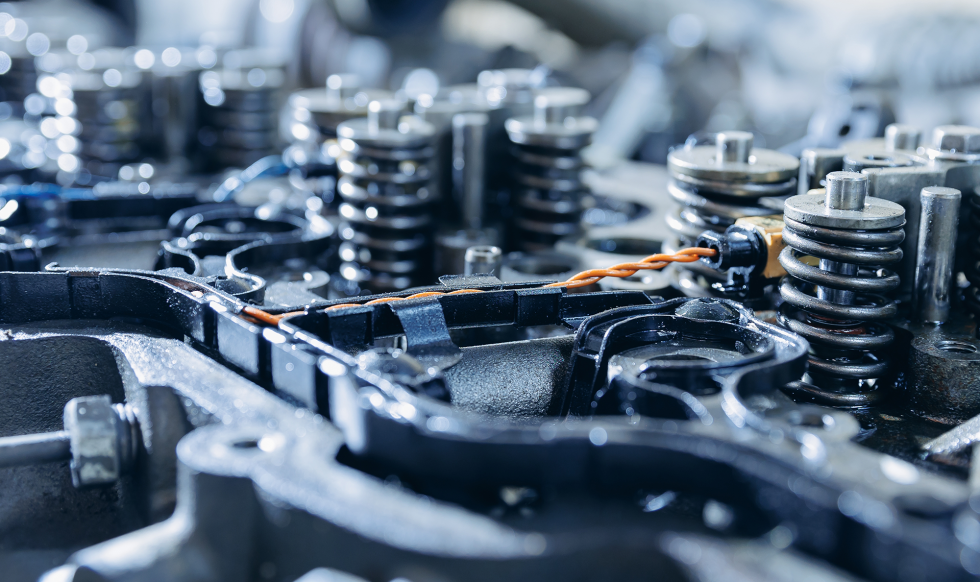

Electrical systems are the lifeblood of modern diesel trucks. From the starter and alternator to wiring harnesses and onboard computers, every electrical component plays a critical role in reliability and uptime. At RG Diesel, LLC in Greeneville, TN, we provide comprehensive electrical services for heavy‑duty diesel trucks used in fleet operations, including Powerstroke, Cummins, and Duramax platforms.

Whether you’re managing delivery trucks, service vehicles, or heavy haulers, our expert technicians diagnose and repair electrical issues with precision to keep your fleet moving safely and efficiently.

Diesel trucks can show electrical issues in many ways. Schedule an inspection if you notice:

- Difficult starts or a no‑crank condition

- Dim or flickering headlights and interior lights

- Dashboard warning lights or error codes

- Battery or charging system irregularities

- Power accessory malfunctions

- Intermittent electrical behavior

Addressing electrical concerns early can prevent breakdowns that take vehicles out of service unexpectedly.

Battery & Charging System Support

Alternator Diagnostics & Repairs

Starter System Services

Wiring & Connector Inspection

Lighting & Accessory Electrical Repairs

Fuse & Relay Testing

Sensor & Module Diagnostics

A healthy electrical system supports dependable starts, accurate performance data, critical safety features, and efficient fuel and engine management. For fleet vehicles, this translates to fewer roadside failures, improved driver confidence, and reduced unscheduled downtime.

At RG Diesel, LLC, we pair diesel‑specific diagnostics with practical solutions designed to keep your fleet’s electrical systems functioning under heavy loads and long operation cycles.

Can electrical problems drain battery life quickly?

Yes. Parasitic draws from shorted wiring, failing modules, or accessory faults can sap battery power faster than a normal drain.

Why does my truck start differently in cold weather?

Colder temperatures place extra strain on batteries and electrical systems. We can test and recommend solutions for cold‑weather reliability.

Do warning lights always mean an electrical fault?

Not always, but persistent warning indicators often point to sensor, wiring, or module issues that should be diagnosed promptly.

Will electrical issues affect engine performance?

Yes. Faulty sensors or poor connections can trigger incorrect engine data and impact performance or fuel efficiency.

How often should fleet vehicles get electrical inspections?

Ideally during every scheduled maintenance visit or at least every 10,000 miles to catch early wear.

- 4×4 Services

- AC Repair

- Brakes

- Diesel Vehicle Care

- Domestic Diesel Trucks

- Electrical Services

- Electronic Services

- Engine & Transmission

- Engine Maintenance

- Fleet Brakes

- Fleet Drive Train

- Fleet Electronics

- Fleet Engine Work

- Fleet General Services

- Fleet Suspension Work

- General Services

- High Performance Brakes

- High Performance Cooling

- High Performance Engine Repair

- High Performance Exhaust

- High Performance Transmission Repair

- High-Performance Suspension

- Miscellaneous Services

- Quick Lube Services

- Transmission Services

- Undercar Services